At Peak Ski Shop Ski Tuning is constantly evolving.

Change is good.

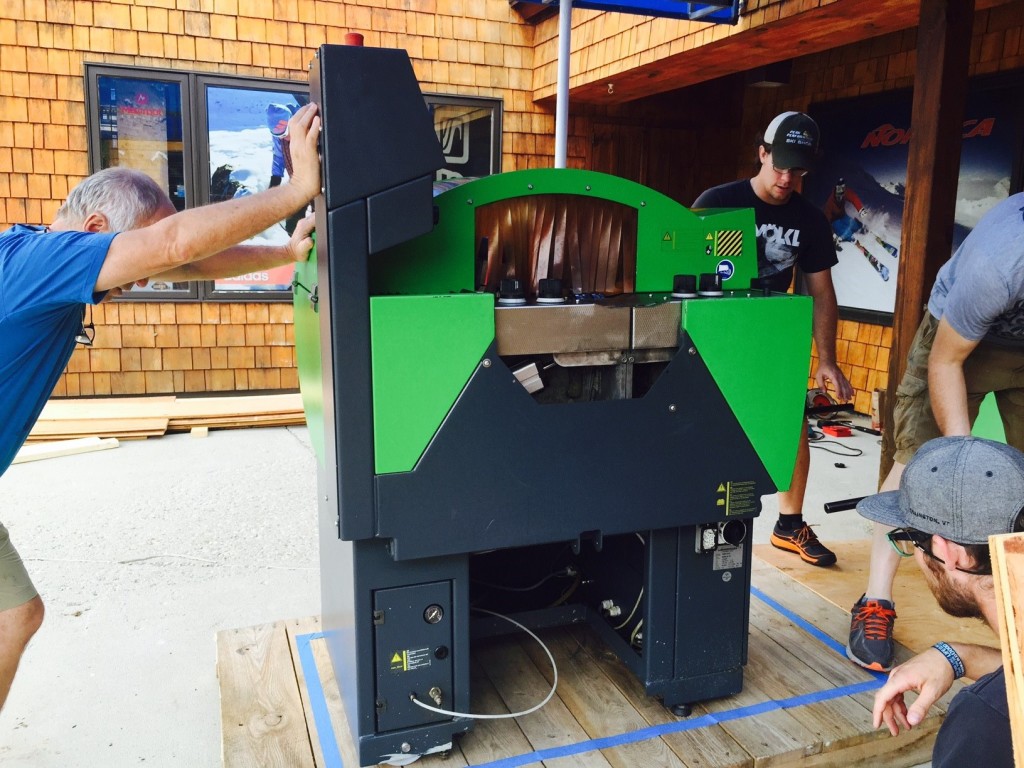

As we move the Wintersteiger Omega and pack up our Wintersteiger Trimjet in preparation for receiving our new Wintersteiger Mercury we are reflecting on how ski tuning at Peak Ski Shop has progressed over the last 26 years. Just as the ski industry and ski tuning technology has evolved, so has Peak Performance Ski Shop.

We strive to be at the forefront of our industry utilizing the latest proven technologies to offer our customers best in class ski tuning. Whether you are a first-time skier out on a pair of our rental skis, a seasoned recreational skier, or a ski racing athlete we offer world cup ski racing quality workshop services and tuning utilizing the highest-tech machinery available.

Here’s the history behind Peak Ski Shop ski tuning:

1988: Reichmann Stone Grinder and Belt. When we opened the store we started out tuning with a Reichmann Stone Grinder and Belt. It was a state of the art ski tuning machine for the time. It was designed to flatten a ski and put a basic structure on it. Quickly we realized we needed something more. (Looking back, the technology that was employed for tuning long straight skis seems rudimentary now.)

1991: Wintersteiger Micro 1. Coming from a precision automotive background, precision ski services and high quality craftsmanship were a priority for our shop. Within the first few years of tuning skis we realized we wanted to offer a higher level of ski tuning. We purchased our first Wintersteiger ski tuning machine, a Micro 1. This machine had a belt and stone, which allowed us to tune base edges and add structure to a ski base. This was one of the first machines that allowed the ability to install a race specific pattern to the skis.

1997: Wintersteiger Trim Disc 90. In 1997, There was a quantum leap in edge sharpening technology when ceramic disk technology for base and side edge tuning emerged. Ski manufacturers were using a ceramic disc edge sharpening machine which created a very precise and smooth edge. Wintersteiger was the first manufacturer to introduce this technology to ski shops with the Trim Disc 90. We knew we had to get one of these machines. The Wintersteiger Micro 90 revolutionized Peak Ski Shop ski tuning and ski tuning around the world. In the end, we found this machine to be very precise for side edges, but technology was still lacking in the ability to create precise base edges on the skis. Race level quality base edges still needed to be set by hand and side edges needed to be checked by hand.

2004: Wintersteiger Sigma RS350. This machine was the beginning of modern ski structuring and the workhorse of Peak Ski Shop ski tuning for 10 years. It was from the first series of machines from Wintersteiger to use digital programming and allowed us to apply strict parameter controlled racing structures. This machine was able to create structures that were specific to DH, SG, SL or GS. With a grinding stone width of 350 mm, besides easily grinding snowboards; we could work much more efficiently with skis, because the stone is divided. We could create two structures at the same time by setting a different structure on either half of the stone. This allowed us to pre-grind on one half of the stone and then follow up immediately with fine grinding on the other half. In addition to tuning for specific racing events, we could also program this machine to tune skis for specific temperatures and snow conditions.

2007: Wintersteiger Trimjet. One of the most sought-after machines on the market, the Wintersteiger Trimjet is built around Wintersteiger’s Ceramic Disc Finish technology. This machine provided precise edge geometry and allowed us to individually and independently adjust angles. This machine changed ski tuning again. The technology of the Trimjet allowed very precise side edges and base edge from .5 to >1 degree. Skis were polished and sharp from the first ski to the hundredth ski – everyday.

2014: Wintersteiger Omega Race 350. In our quest for higher quality precision race (and recreational) ski tunes we purchased a Wintersteiger Omega Race 350. This machine expanded the variety of structures that could be used keeping pace with the structures that were being offered by the ski manufacturers on their highest level race skis. The centering unit on the Omega RS 350 supports easy and precise grinding of center specific racing structures (e.g., hoop and arrow structures) which was another bonus for Peak Ski Shop ski tuning.

2015: Wintersteiger Mercury with Race Service. In our never-ending quest for the highest quality ski tunes we have now purchased a fully automated Wintersteiger Mercury ski tuning machine with the race service option. We’ve watched the evolution of automated ski tuning machines. It took 15 years, but in 2013 the automated machines really started to take off in popularity, not just in Vermont but all over the world. Until now, we were still not convinced automated ski tuning machines could do as good if not better than a manual machine. We now feel the latest Wintersteiger Mercury ski tuning machine really does surpass manually operated machines. Everyone uses machines differently because everyone has different needs. Some shops have a standard Wintersteiger Mercury automated ski tuning machine, it does a fantastic job on recreational skis. We bought a Wintersteiger Mercury ski tuning machine with race programming packages. This machine will allow us to do very detailed race specific ski tuning as well as incredibly high quality recreational tunes. The combination of our skilled technicians and the precision of a race machine will make all skis, both recreational and race skis, ski better.

Peak Ski Shop ski tuning machines have changed and evolved over the last 26 years, but one thing that has not changed is Peak Performance Ski Shop’s precision craftsmanship, attention to detail and commitment to quality. We’ve always been known as ‘the place to get skis tuned in Killington’ whether you were a recreational skier or a ski racer. That’s who Peak Performance Ski Shop is and how we’ve built the store.